Robots are widely used in manufacturing and other industries, but they also have the potential to be used in more businesses than ever before. On this page, we will go over some of the advantages and disadvantages of using robots in the workplace.

Advantages of Robots in the Workplace

Many people don’t realize just how much benefit robot technology can bring to the workplace. If you are interested in learning more about how these mechanical wonders can make an impact on your business, keep reading.

Robot Human Collaboration

Human-robot collaborations are growing in the workplace, with robots designed to work alongside humans. While some may fear that these robots will replace human workers, this is not the case. Instead, they can act as an assistant who can lift heavy objects or perform other tasks that might injure a human worker.

Robots are Faster Than Humans

One area where robots work faster than humans is in factory settings because they can perform tasks repeatedly without making mistakes. They also can work constantly throughout the day without breaks, which allows companies to produce goods much faster and cheaper

Robots can Perform Dangerous Tasks

Robots are being used for tasks that can be very dangerous or tedious to complete, such as welding steel beams together on a construction site. And it’s predicted that the future will include many workers who work alongside these robots instead of doing hazardous jobs themselves.

Robots Are Better at Precision Work

Many people would say that robots are more precise than humans. That is why they excel at tasks like painting cars and building circuit boards. Some people might think this is a bad thing because it will take away jobs, but it makes the work faster and it frees up workers to do more creative things.

Robots Work with Greater Efficiency

Robots never get angry at their boss and always follow orders precisely, which makes them more efficient than human employees. As technology advances, we will see more jobs performed by robots because it’s cheaper for companies to purchase one robot rather than hiring multiple employees with benefits, vacation days, and sick leave.

Robots Can Lead to Higher Profitability

Higher profitability is the future of robotics. The use of robots has grown exponentially in recent years and many companies are now seeing how it can lead to higher profitability. For example, a company like Amazon can be more profitable since they can cut costs by using robots for inventory management and packing deliveries, and in the future robots might even handle deliveries.

Robots Can Reduce Waste

Robots have been found to reduce waste in manufacturing. They are more efficient, accurate, and productive than humans. This is good news for companies who are looking to decrease their production costs by reducing waste that occurs during every step of the manufacturing process.

Robots Create New Jobs

Robots are taking over many jobs. In direct response to this, there has been a rise in jobs that require robotics skills. On top of that, these robots increase efficiency and lower costs which is great for freeing up resources so companies can hire more people. Plus, robots can do more than just create jobs; they can also establish new industries in healthcare and other important fields like space travel too.

Robots Can Work 24/7

Robots can be programmed to work 24 hours a day, 7 days a week without getting tired or slacking off on the job. These benefits make them a great choice for factories, but there is also much more potential with robotic technology as it continues to develop.

Disadvantages of Robots in the Workplace

Although robots are great for performing repetitive tasks that humans find tedious, there are serious disadvantages to having them in the workplace. Read on to learn about some of these disadvantages and how robots may not be as beneficial as you think.

Robots Can Increase Unemployment

The use of robotics in the workplace is on the rise. With companies utilizing robots to do jobs that are typically done by humans, our unemployment rates are likely to increase as more and more people are replaced with machines.

Robots Can Increase Income Inequality

For years, robots have been taking over factory jobs. Now they are making their way into retail and other service-based jobs that people once thought were safe. With the increasing automation of labor in these industries, there is a concern that owners will be able to hire fewer workers for lower wages without fear of competition from other businesses. This means that income inequality may continue to grow with this new form of technological innovation.

Robots Are Expensive

The price of a robot varies depending on how it will be used. For example, if you’re looking for something that can work in an office setting or warehouse, then this would be considered “light duty.” If you need to have something that works outside or in dangerous conditions like construction sites then these are called “heavy duty” robots.

The prices for each one of these types of robots ranges from $10,000 up to $1,000,000 +. So before making any decisions about what kind of robot you need to invest in it’s important to see if it’s within your business’s budget.

Robots Require Maintenance

Robots are a fantastic invention, but they come with a cost. You have to maintain them and replace the parts that wear down over time. And it is important to know how much it costs to maintain each robot so you can plan and budget accordingly.

Robots Require Highly Paid Skilled Operators

Robots are becoming more and more common in manufacturing plants. One of the biggest issues with robots is that they require highly skilled operators, who can be hard to find. This means that there can be a shortage of qualified people for these jobs so companies have to pay these individuals an incredibly high wage.

Robots Can Pose a Safety Hazard

The use of robots in manufacturing has increased dramatically over the past decade, but some safety hazards need to be addressed. Most notably, if a robot malfunctions and starts moving quickly, it could cause serious injury or death.

Robots Have High Energy Demands and Large Carbon Footprints

Robots are becoming increasingly integrated into everyday life and as a result, their energy needs and carbon footprints have become important considerations. Additional electricity demand is also created by charging batteries for mobile robots like self-driving cars or drones.

Robots Have Limited Dexterity

Robots are an amazing invention because they can do things humans can’t. They can be programmed to perform tasks that would take a long time for humans to complete, and they don’t get tired or need breaks as we do. The downside is robots have limited dexterity compared to humans so their ability to manipulate objects is very basic at best, and this limits what kind of work they can perform.

Robots are Restricted to their Programming

Robots are restricted to their programming. In most cases, they cannot learn, adapt or change. And it is hard for them to have any agency if they get stuck or need to adapt. That’s why there will always be jobs that humans need to do because robots will always have a hard time competing with millions of years of evolution.

Types of Robots in the Workplace

In today’s world, robots are becoming more and more common. They’re used in many different ways from the manufacturing industry to robots for personal use. Read on to learn about each type of robot used in the workplace from Industrial Robots, Autonomous Robots, Collaborative Robots, Teleoperated Robots, and Human Assisted Robots.

Industrial Robots

Industrial robots are now a common sight in manufacturing plants and warehouses. They’re used for repetitive tasks like spot welding, material handling, and packaging. But recent advances in robotics technology have also made them more versatile than ever before.

Autonomous Robots

Autonomous robots can function without human intervention. These machines can sense their environment, make decisions based on that information, and take actions accordingly.

They have the potential to be safer than current robotic technologies because they can react quickly enough to avoid accidents or injuries in dangerous environments.

Autonomous robots could also increase productivity by allowing humans more time for other tasks while machines handle tedious or repetitive work.

Some of these bots are even capable of learning new skills through observation and experience, which means they might eventually act as personal assistants rather than just performing specific tasks.

Collaborative Robots

Collaborative robots are becoming increasingly popular in manufacturing and other industries. These robots can be used for a variety of purposes, including packaging, assembly, welding, sorting items on conveyor belts, and loading machines with materials.

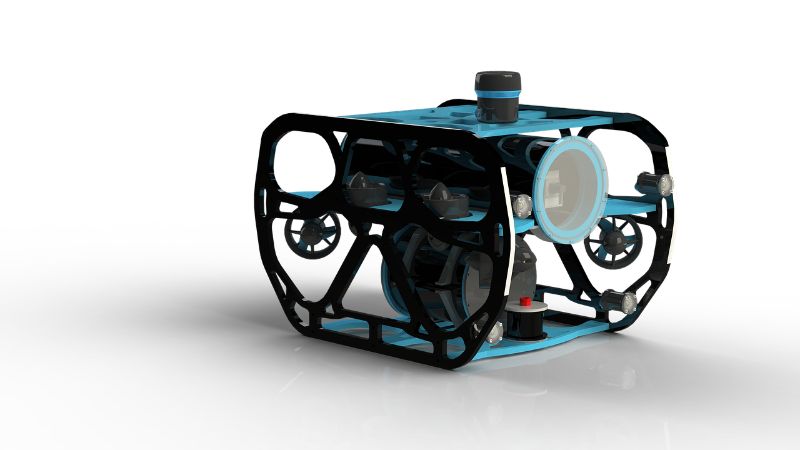

Teleoperated Robots

Teleoperated robots are one of the first types of modern remote-controlled robots ever developed. As technology advances, they will become even more prominent. Teleoperated robots can be used for many different purposes, such as search-and-rescue missions or working alongside humans to do dangerous tasks that people don’t want to risk their lives doing.

Human Augmented Robots

Human Augmented Robots are not just an idea that exists in the future, they are being created right now. The term “human augmented robot” is used to describe a human with various parts of its body assisted by robotic systems. These robots are being designed for combat purposes and they are even being used in factories to help workers lift heavy items with less risk of injury.